- Welcome to our website

- Email:[email protected]

- Email:[email protected]

ball mill 210 260

- Accueil

- >

- ball mill 210 260

ball mill 210 260

ball mill 210 260 :

BALL MILL FOR ALL YOUR NEEDS - FTM Machinery

2021年9月18日 Dry ball mill: The ball mill needs to be equipped with an air induction device, a dust exhaust pipe and a dust collector. The structure is more complicated, and

Consulter un spécialiste

Ball Mill 210 260 - stahbud

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material

Consulter un spécialiste

3D Ball Mill - 3D Ball Mill

產品介紹. 產品特色 : 1. 世界唯一X,Y,Z3軸同步運轉混碎料機,實現了”無重力”混鍊功能. 2. 高速3次元同時運轉可實現非臨界狀態,使粒子不凝集、不固化。. 3. 能將不同比重、黏度

Consulter un spécialiste

6-552-05 Porcelain Ball Mill 210 【AXEL GLOBAL】ASONE

Japanese. Features. It can be wet or dry, and has excellent acid and salt resistance. Spec. Diameter (outer diameter x height mm): φ215 x 280. Capacity: 4.8L. Attached ceramic

Consulter un spécialiste

Ball Mill - Shanghai DingBo heavy industry machinery co., LTD.

Ball mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. In

Consulter un spécialiste

Nova S Ball Mill Bühler Group

Nova S ball mill is the preferred solution for fine-grinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fat-based

Consulter un spécialiste

Porcelain Ball Mill 210 SABP-655205

Porcelain Ball Mill 210就在科研市集。 科研市集提供【先出貨後付款】、【低價免運】,【量大殺價功能】等服務,是全台灣第一間集科研商品以及科研服務為一體的一站式線上

Consulter un spécialiste

Ball Mill 210 260 - ruta12.es

The ball mill for lime is a horizontal cylindrical rotating device, driven by external gears, two bins, and a lattice ball mill. The material enters the first silo of the mill spirally through the

Consulter un spécialiste

Ball Mill Catalogue

2019年6月8日 A ball mill is partly lled with steel balls (some are cylindrical shaped cylpebs) that impart a tumbling and cascading action when the mill rotates around its

Consulter un spécialiste

Ball Mill 210 260 - stahbud

Ferro Industrial Specialty Materials InstantColor. ball mills, much less production time, and much less waste. All this is offered in the complete color ... 210 960 Zr‐Si‐Pr‐V / 220 942 and 220 955 Zr‐Si‐V / ... 260 952 Zn‐Cr‐Fe / 260 954 and 260 946 Zn‐Al‐Cr‐Fe / 260 955 Zn‐Mn‐Fe‐Cr With the exception of stain 260 955, all these stains

Consulter un spécialiste

The Ultimate Guide to Ball Mills - Mining-pedia

2019年8月14日 5. The size of the ball mill is large, and it is necessary to carry out lifting work during the process of replacing the ball mill liner. The hoisting ball mill liner is the responsibility of the hoist. The lifting process requires attention to the operation of the wire rope and the hook. 6.

Consulter un spécialiste

ball mill 210 260

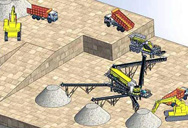

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉 The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 m ... ball mill 210 260 POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE.Consulter un spécialiste

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉 The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 m ... ball mill 210 260 POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE.Consulter un spécialiste

Ball Mill 210 260 - ecuriedeslacs-civry

ball mill 210 260 - enzos-raben. ball mill 210 260. ball mill small ball mills for sale ball grinding mill . Features What Is Ball Mill Ball mill is also known as ball grinding mill Ball mill is the key equipment for recrushing after the crushing of the materials It is widely used in cement silicate products new building materials refractories chemical fertilizer black and

Consulter un spécialiste

Ball Mill (Ball Mills Explained) - saVRee - saVRee

Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant. For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% charged.

Consulter un spécialiste

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉碎仪

Download. The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch. The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and ...

Consulter un spécialiste

20 Mm Ball Nose End Mill, 210 Mm at Rs 700/piece in

AKR Tools And Traders - Offering 20 Mm Ball Nose End Mill, 210 Mm at Rs 700/piece in Chennai, Tamil Nadu. Get Ball Nose Cutter at lowest price ID: 11886497362

Consulter un spécialiste

Ball Mill 210 260 - kpilawski

Ball Mill 210 260. 260 ball mill - naturavertical.es. Ball Mill 210 260 . Ball Mill - Zoneding. The ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries, such as cement, silie, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and ...

Consulter un spécialiste

Effect of operating parameters in stirred ball mill grinding of

Keyword (en) Stirred vessel Grinding (comminution) Ball mill Coal Energy consumption Laboratory scale Experimental study Grain size analysis. Keyword (es) Aparato agitado Molienda Molino bolas Carbón Consumo energía Escala laboratorio Estudio experimental Granulometría. Classification. Pascal. 001 Exact sciences and technology / 001D Applied ...

Consulter un spécialiste

3D Ball Mill - 3D Ball Mill

# 3D Ball mill 產品說明 # 3D Ball mill 運作模擬 產品規格 型 號 規 格 3D-210-D2 .中型 .桌上型雙軸3向同步混碎料機 .腔體尺寸Φ 210mm .最大加工數量100g(ml)-1,200g(ml) 3D-80 .小型 .3向同步混碎料機(崁入型) .腔體尺寸Φ 80mm ...

Consulter un spécialiste

Population balance modeling approach to determining the mill

2022年1月1日 The ball charge contained only mono-size balls. In the 29.2 cm ball mill, balls used were 1.27, 1.90, and 2.54 cm in diameter. In the 40.6 and 61.0 cm diameter ball mills, balls used were 1.90 and 3.81 cm in diameter. The top size of the feed charge varied from 150 to 2380 μm.

Consulter un spécialiste

Joyal-Ball Mill,Ball Mill For Sales,Ball Mill

2024年2月18日 Ball mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Besides, it is mainly applied in

Consulter un spécialiste

Ball Mill Ball Mills Wet Dry Grinding DOVE

6 天之前 DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (0.3 TPH – 80 TPH). With over 50 years experience in Grinding Mill Machine fabrication, DOVE Ball Mills as ...

Consulter un spécialiste

Ball Mill - an overview ScienceDirect Topics

The ball mill is a cylindrical drum (or cylindrical conical) turning around its horizontal axis. It is partially filled with grinding bodies: cast iron or steel balls, or even flint (silica) or porcelain bearings. Spaces between balls or bearings are occupied by the load to be milled.

Consulter un spécialiste

Nova S 球磨机 布勒集团 - BUHLERGROUP

独特的珠磨机技术. Nova S 球磨机可适用于各种浆料的精磨解决方案,例如代脂、涂抹酱、馅料和涂层奶油、可可浆料、坚果酱及其他脂性浆料。. 独特的研磨腔可在低温下实现一步研磨,确保您的产品具有稳定的高质量。.

Consulter un spécialiste

210 Davis Mill Rd, Ball Ground, GA 30107 realtor®

See photos and price history of this 5 bed, 5 bath, 3,192 Sq. Ft. recently sold home located at 210 Davis Mill Rd, Ball Ground, GA 30107 that was sold on 07/20/2023 for $675000.

Consulter un spécialiste

Ball mill: Principles, construction, working, uses, merits, and ...

2024年1月28日 1. Cylindrical Shell: The ball mill consists of a hollow cylindrical shell that rotates about its axis. The shell is usually made of steel, stainless steel, or rubber. 2. Liners: An abrasion-resistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action.

Consulter un spécialiste

Exploring ball milling theory: A comprehensive guide

2024年7月12日 Principles of Ball Milling. Ball milling is a mechanical process that involves the rotation of a drum containing grinding media, typically steel balls, at a high speed. The materials to be milled are loaded into the drum, and as the drum rotates, the grinding media collide with the materials, causing them to break down and reduce in size.

Consulter un spécialiste

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

A ball mill consists of various components that work together to facilitate grinding operations. The key parts include the following: Mill Shell: The cylindrical shell provides a protective and structural enclosure for the mill. It is often made of steel and lined with wear-resistant materials to prolong its lifespan.

Consulter un spécialiste

- vibration sur broyeur à marteaux concasseur

- sable et de ciment humide malaxeur à vendre

- concasseurs à cone fournissent

- système de depoussierage pour les concasseure

- la mine et de la fonderie concasseur à machines craigslist

- moulin de ma tre de mais à vendre

- mâchoire concasseur broyeur de pierres

- le broyeur a boulets fabricants de litalie et de lTunisie

- facteurs qui influent sur la capacité de production et mamarocry

- shema pour broyeur sturvevant model 3b sipactor pin mill

- MyFord machine Granding

- broyeurs à marteaux europages

- la fabrication du gravier facebook

- alto cromo 3 bajo bolas de molienda de hierro fundido

- de nouveau concasseur de cendre